Three Innovative Teams Designing Sustainable Products in Italy

Table of contents

Sustainability is a very complex concept to incorporate into innovative products, as it can be impacted by many factors and processes. Here are three companies creating innovative and sustainable products in Italy.

Sustainability is a very complex concept to incorporate into innovative products, as it can be impacted by many factors and processes. A company has to analyze, understand, and embed the entire product life cycle while working on the solution.

Some of those complex core phases include:

- Raw material availability and extraction, as it is usually a very carbon consuming process.

- Material transformation and production assembly.

- The after-use recycle process, which is the energy and items needed to reuse the material or to discard it.

- Finally, the nature of the energy used during every process.

Successful companies build small teams of researchers and designers to tackle these phases and to innovate processes that drastically decrease the level of pollution generated given the same product or service. Here are three companies leading the way in Italy.

SUMUS

SUMUS Italia produces bags for organic waste that are entirely compostable while resistant to liquids, holes, and rips.

The idea for the company's bags was born at the end of 2005 by the current President and CEO of the company, Damiano Chinello. During a trip in Northern Europe he noticed the usage of virgin paper for the collection of domestic organic waste. Given his deep knowledge of paper as a paper technician, he was very aware of the characteristics of this material and the processes that could be implemented to create the same product using a recycled raw material.

After returning home he began to experiment with creating an innovative bag for organic waste that could maximize the entire organic waste life-cycle: the longer the waste stays in people’s houses without creating bad smell, the less often collection will happen, meaning less energy will be wasted in logistics. Likewise, using recycled paper at the end of its life for this usage brings the same quality, so there’s no need for virgin paper. After designing this very ambitious circle, he started the process to produce the first bags and to study the real impact. With the help of Renato Fancello, the company's R&D leader, the innovation soon received a patent worldwide.

The SUMUS bags are effective as they enable organic waste to lose mass and volume while staying at home without breaking or smelling. That is possible thanks to the mobile internal intermediate bag bottom, which is the real revolution that radically differentiates these bags from the others. It isolates the bottom of the bag from direct contact with waste, protecting it and facilitating the aerobic activity. This structure creates a volume of air, a sort of lung, between the bottom of the bag and the intermediate bag bottom. The aerobic activity of the waste generates a natural “forced draft” that is similar to a chimney. Every time the warm air created in the degradation process of waste mass goes up, the cold air contained at the bottom also goes up. This virtuous cycle is the base for the efficiency of this SUMUS bag.

What’s SUMUS’s impact?

In 15 years, the company has sold 1.5 billion bags, directly impacting the whole production chain given that 50% of the organic waste is used to create biogas and that when organic waste is collected using bioplastic materials that keeps water, the process becomes way less effective. What’s the difference? The paper used to become organic waste itself melts in this specific phase, so there is no need to recycle it in a different way — there is an homogeneity of materials. This gives a higher production of high-quality biogas and avoids the so-called “dragging effect,” that is typical of other packaging, which needs to be opened in order to process organic waste in biogas production (applicable for the 50% of organic collection)

Years of research and experience has led SUMUS to be chosen many times to collaborate with the top universities in Italy on waste life cycle assessment.

Why is SUMUS’s team so valuable?

They know the market and the industry well, from every feature of paper to the recycling processes. They are also committed to creating a culture based on their conviction that every kind of waste must be temporary to people and that products shouldn’t be created to end up as useless waste. This is also the reason why they are working with many partners in order to challenge the model that sees extraction, production, and disposal happening far away from the actual customer.

FLEEP Technologies

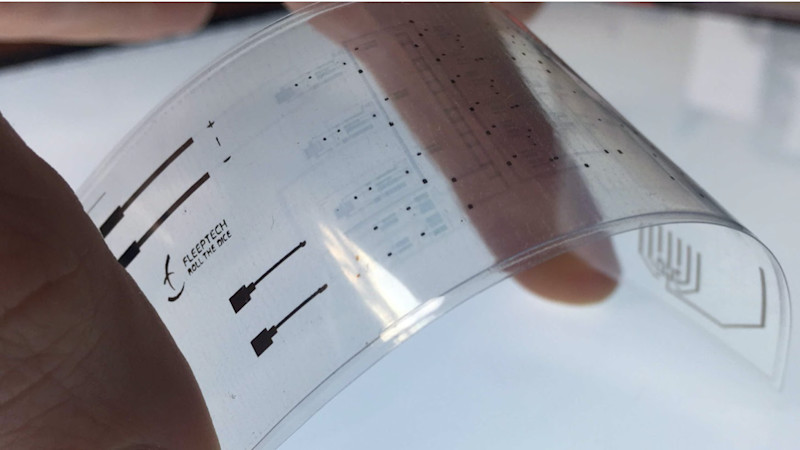

FLEEP Technologies makes flexible and recyclable electronics that are printed on plastic in a scalable industrial environment to create a more integrated and sustainable technological future

The idea of printing plastic circuits is not new, as it was born from a field of research called “plastic electronics,” which was discovered in 1965 after Nobel Prize-winning scientists Heeger, MacDiarmid, and Shirakawa demonstrated the possibility for plastic materials to conduct electricity, but only took off in the early 2000's.

FLEEP Technologies was founded many years later, in 2019, from the intuition of CEO and founder Giorgio Dell'Erba. Giorgio had started his PhD at Politecnico di Milano in 2013 when he met Mario Caironi, a senior researcher at the Italian Institute of Technology who was working on incredible new materials for organic transistors. Given Giorgio’s background in electronics, he had the intuition to shift the research on creating electronic circuits for devices.

The turning point for FLEEP Technologies came when a multinational company asked them to test this technology for the pharmaceutical packaging industry. This request turned the academic study into a real entrepreneurial project.

__How can a product made of plastic be environmentally friendly?__n

The answer to this lies in knowing how standard silicon technology integrated circuits are manufactured. They need:

- High temperature (up to 1500°C)

- High vacuum (deep-space like)

- Subtractive processes

All these aspects make common electronics not environmentally friendly at all. In addition, electronics contain earth-rare materials, precious metals, and toxic components that can make devices extremely hard, if not impossible, to recycle and/or recover.

FLEEPtech products employ only plastic. If appropriately treated, the material is recyclable and can be almost fully recovered, making the electronics recyclable. Also, their manufacturing process is additive, meaning no waste of material and with processing temperatures below 100°C. All of these aspects make this technology way more environmentally friendly compared with the market standard.

How can scalable printing techniques have a positive impact on the planet?

Market reports say that by 2025 there will be more than 25 billion IoT devices worldwide. The environmental impact of such an enormous number of non-recyclable devices will be massive. Therefore, a strong shift in the paradigm of electronics manufacturing will have a huge impact on our world health.

Why is FLEEPtech’s team so valuable?

FLEEPtech’s team is made up of five people with solid and extreme technical skills that fit into the specificity of the business: four members have a PhD (either in Electronics or Physics) with specific knowledge of the field and one is a MSc in Material Science.

Printed electronics, as with many other complex industries, need a meld of many variations of expertise: chemistry and material science are the base, physics behind electronic devices is needed for testing concepts, and electronics to find the best way to put such devices together into a circuit. Their team covers all these aspects.

Vitesy

Vitesy designs and creates Italian-made green IoT devices that monitor and purify internal air.

Vitesy was born from the inspiration that hit co-founders Paolo Ganis, Alessio D’Andrea and Vincenzo Vitiello while studying a NASA paper on indoor pollution back in 2015. Equipped with their new-found awareness that internal pollution can be up to five times greater than external pollution and their strong technical product design backgrounds, they started working on a product that could purify air indoors while appearing as a design item.

Their escalation has been very quick: they presented the very first prototype at CES in Las Vegas in 2016. After this experience, the team was selected for a 3-month acceleration program in Silicon Valley. During the program they launched their first kickstarter campaign, raising four times their initial goal.

But the real turning point arrived thanks to a €2 million investment that Vitesy received from the European Union's Horizon 2020 program – the EU’s most important funding opportunity, less than 2% of applications gets funded. This enabled the team to rapidly grow: in a few months the startup went from 3 to more than 20 employees. The talent that the founders wanted on board were people highly skilled from an R&D an IT perspective: Vitesy products easily enter in people’s houses thanks to their lovely design, but the product core is based on technological assets that enable the analysis of the air and the optimization of air quality cleaner capabilities.

What makes Vitesy product so innovative within the indoor air cleaner market?

Vitesy products are unique in many ways, as hidden behind the design is the innovative solution that is made by the combination of three core elements:

- The plant is a natural filter, full of microorganisms that physiologically eat carbon dioxide and generate oxygen, as well as nanomaterials like titanium dioxide that accelerate the exchange thanks to LED activation

- Sophisticated sensors that understand the pollutants the plant is receiving throughout the day and during different seasons.

- Data collection and analyzing the difference of pollution levels in different areas, regions, and countries enabled the team in learning how to implement a more sensitive product based on the external situation.

__How does Vitesy create a positive impact on the planet’s health? __

The impact that Vitesy brings to the market is deeply related to its core technology and design: 99% of indoor filters must be replaced every 3 or 4 months, which causes 100 million wasted filers over the course of 5 years. Vitesy technology, meanwhile, is filterless.

Other remarkable aspects of the product are that it’s made with recyclable materials and that the entire product has a modular design that ensures it is easily disassembled and recycled.

Furthermore, the team is super focused on logistics, minimizing the operations chain as a fundamental part of the customer experience and the pollution generation – Vitesy has in fact selected the best manufacturers in the northern region of Italy, thus combining extreme quality with low impact in emissions during the production process.

Finally, as a concrete and quick donation to the planet, the startup is planting 10 trees for every product they sell - they have already planted more than 100k trees. For the team this is not only an action, but a real expression of the company culture.

--

The Org is a professional community where companies can show off their team to the world. Join your company here to add yourself to the org chart!

The ÂÜŔňÂŇÂ× helps

you hire great

candidates

Free to use – try today